Cut To Length Line Paid

1 year ago - Bangladeshi educational institutions - Banbury-Don Mills - 27 views$ --

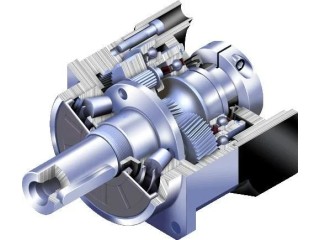

Cut To Length Line 1. Introduction Light gauge cut to length line is a machine that performs a series of processing operations such as uncoiling, leveling and shearing of metal plates. The large sheet opener can generally process cold rolled coils with a thickness of 0.3mm ~ 3.0mm. In the early days, the sheet opener can only process the cold-rolled coil with the maximum width of 1300mm. However, with the wide application of 1500mm cold-rolled coil, the 1500mm width opener soon occupied the market. The processing capacity of cold rolling leveler is mainly reflected in leveling, surface protection, stamping and so on. Uncoiling leveling cross cutting palletizing production line: This series of production line is used for uncoiling, leveling, sizing and shearing metal coils of different specifications into flat plates with required length and width. It is suitable for processing cold-rolled plates, galvanized plates, color coated plates and stainless steel plates. This series of production lines are equipped with loading trolley 鈫?uncoiler 鈫?feeding device 鈫?traction leveling machine 鈫?transition bridge 鈫?deviation correction device 鈫?servo feeding 鈫?plate shears 鈫?conveyor belt 鈫?blanking 鈫?stacking. The maximum running speed of this series of production line is up to 120 m / min, and the sheet metal can be protected flat without scars; Feeding is driven by servo motor, with high shearing precision; Double palletizing and discharging, efficient and fast. 2. Specifications/Technical parameters General Induction of cut to length lineCut To Length Lines can do uncoiling, feeder .leveling, cross-cutting to length work. It mainly includes uncoiler, feeder straightener, shearer, hydraulic system, pneumatic system and electrical system, etc., the line can make sure of accurate feeding and shearing. It can be widely used in mild steel metal coil materials. Cut to length line is controlled by PLC controlled the length measurement. The information of length, shearing numbers and speed can be input to the PLC systems. When the need shearing length is reached, the machine can cut automatically. The line speed can be adjusted, and whole line can operate easily. LIST OF EQUIPMENTS UNDER SCOPE OF SUPPLY1. Coil car 2. Decoiler 3. Leveler 4. Side Guide Roller 5. Shearing machine 6. Electrical System. 7. pneumatic system 8.hydraulic system Technical dataMaterial 锛?CR, GI.HR Coil Weight: 20000KG Strip Width: MAX 1500MM Strip Thickness 0.3-3.0MM Coil O. D: 1600 mm (max) Coil I.D: 508mm (max) Feeding Accuracy: + 0.5 mm Feed Speed: 20m/min 3. Product detail 1. Application: construction materials, raw materials etc. 2. Original: Xiamen, China 3. Certification: ISO9001, CE etc. 4. Price: Negotiable 5. Voltage: 380V 50Hz, the voltage can be as local demand 6. Payment term: TT, LC 7. Delivery date: Negotiable 8. Packing: Naked package with poly wood case for control box 9. Market: ASEAN/Middle East/ South Asia/North America/Russia 10. Warranty: 1 year 4. Certificates 5. Our factory Our factory was established in 2014, which covers an area of MORE THAN 10,000 SQUARE METERS. With 20 YEARS PROFESSIONAL EXPERIENCE, Meanwhile, we are the main drafter standard of China Non-standard roll former manufacturer and exporter of high quality roll forming machines in China. We are an ISO9001 approved company, and have European CE certification 6. Advantage 1. With a servo motor, speed precision is virtually ensured. 2. The equipment is structurally sound and performs well; 3. Extremely high output efficiency; 4. Less material waste, lower manufacturing costs, and less reliance on people. 7. FAQ Why should you select us? 1.In Xiamen, China, we are a well-known manufacturer of customized roll forming machines. 2.QUALITY CONTROL DURING THE ENTIRE PROCESS OF MANUFACTURING 3.Prior to packing, conduct a general inspection of the fixings. 4.All of our machines have received ISO 9001 certification. 5.providing long-term servicing for all sorts of machinery and parts 8. EXHIBITIONS/MEETINGS 9. Direct Contact InformationCut To Length Line website:http://www.reliancerollformers.com/cut-to-length-line/